Energy conservation in factories is becoming increasingly paramount in the face of climate change and escalating energy costs. Yet, the common misconception is that improving energy efficiency necessitates a decline in productivity. This article delves into various strategies that can be employed to conserve energy in manufacturing settings without compromising output.

1. Understanding Energy Consumption

To initiate a successful energy conservation strategy, it is crucial to comprehend where and how energy is consumed within factory operations. Conducting a comprehensive energy audit enables stakeholders to identify inefficiencies, wasteful practices, and the specific processes that consume the most energy. By applying metering technologies, factories can gain insights into real-time energy usage patterns and pinpoint high-energy-consuming machinery or processes.

2. Implementing Energy-Efficient Equipment

One of the most effective ways to reduce energy consumption is by upgrading to energy-efficient machinery. Equipment that meets high-efficiency standards can significantly reduce energy usage without sacrificing output. For instance, Variable Frequency Drives (VFDs) allow motors to operate at optimal speeds, thus conserving energy by matching motor performance to actual load requirements. Continuous investment in state-of-the-art machinery is an investment in sustainability.

3. Refining Lighting Systems

Lighting often represents a substantial proportion of a factory’s energy expenditure. Transitioning to LED lighting systems offers a pragmatic solution. LEDs provide increased luminosity while using a fraction of the energy consumed by traditional fluorescent or incandescent bulbs. Moreover, incorporating motion sensors and timers can ensure that lighting is only utilized when necessary, further enhancing energy conservation efforts.

4. Emphasizing Process Optimization

Lean manufacturing principles emphasize efficiency and waste reduction. By streamlining processes and reducing idle times, factories can minimize energy usage without negatively impacting productivity. Techniques such as Kaizen, which focus on continuous improvement, empower employees to identify energy waste in their jobs. This grassroots approach often yields innovative solutions for energy conservation that may not be evident to management.

5. Harnessing the Power of Renewable Energy

Integrating renewable energy sources, such as solar panels or wind turbines, can dramatically reduce a factory’s reliance on non-renewable resources. While the initial investment may be substantial, the long-term benefits of energy independence and sustainability are undeniable. Additionally, combining renewable energy with energy storage solutions allows factories to utilize energy more efficiently, cutting down peaks in energy demand.

6. Enhancing Employee Engagement in Energy Conservation

Employees play a crucial role in energy conservation. Establishing an energy-saving culture requires engaging employees at every level. Training sessions and workshops can educate staff about the importance of energy conservation and practical measures they can take in their day-to-day activities. Implementing incentives for employees who contribute innovative energy-saving ideas can encourage active participation and foster a sense of ownership over the factory’s energy consumption practices.

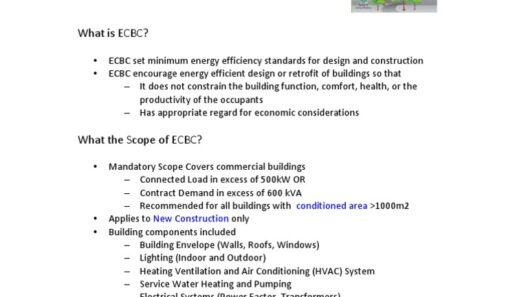

7. Insulating and Maintaining Facilities

Proper insulation and regular maintenance of buildings and equipment are vital for minimizing energy loss. Factories that are well-insulated prevent heat from escaping in winter and reduce the burden of air-conditioning in summer, thus maintaining a comfortable working environment while conserving energy. Regular maintenance checks on heating, ventilation, and air conditioning (HVAC) systems ensure optimal performance, which not only saves energy but also prolongs equipment lifespan.

8. Smart Manufacturing and IoT Technologies

The advent of smart manufacturing, driven by Internet of Things (IoT) technologies, enables real-time data tracking and automation in factories. Smart sensors can monitor energy usage and identify patterns, enabling predictive maintenance of equipment and early identification of inefficiencies. Utilizing data analytics, factories can make informed decisions that optimize energy consumption while maintaining peak operational performance. This approach allows for an agile response to fluctuating demand without compromising on energy conservation.

9. Recycling and Waste Management

Implementing effective recycling and waste management systems can also contribute to energy conservation. Efficient use of materials reduces the energy required for production processes. Factories should explore options to repurpose waste materials into the production cycle, thereby minimizing overall resource consumption. This not only conserves energy but also aligns with sustainable manufacturing practices, enhancing the factory’s corporate social responsibility profile.

10. Monitoring and Continuous Improvement

Energy conservation is not a one-time effort; it demands continuous monitoring and adjustment. After implementing energy-efficient technologies and practices, ongoing assessment through energy management systems allows factories to track progress and adapt strategies as necessary. Utilizing key performance indicators (KPIs) specific to energy consumption can help identify areas for further improvement, ensuring that energy conservation remains a dynamic part of factory operations.

In conclusion, energy conservation in factories need not come at the expense of productivity. By embracing innovative technologies, optimizing processes, engaging employees, and fostering a culture of sustainability, manufacturers can embark on an energy-efficient transformation. This shift not only curtails costs but also contributes towards mitigating the impacts of climate change, ultimately fostering a more sustainable future for all stakeholders involved.