In the realm of engineering mechanics, particularly in materials science and structural analysis, understanding the behavior of materials under various loading conditions is paramount. Among the methodologies employed to evaluate the strength of materials are the Maximum Shear Stress Theory and the Maximum Distortion Energy Theory, each offering unique perspectives on material failure. This exploration seeks to elucidate which of these approaches may be considered more conservative in terms of ensuring that designs prevent failure while optimizing material usage.

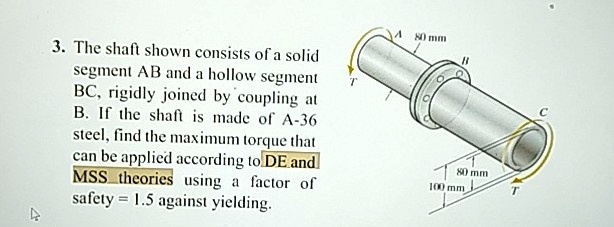

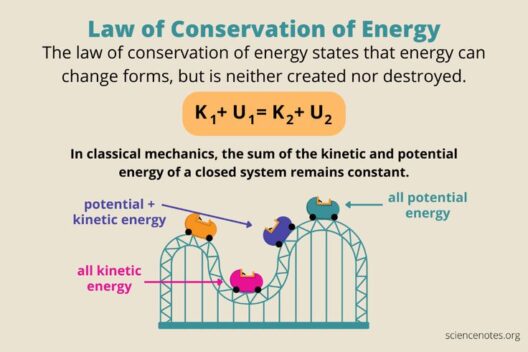

To begin, it is essential to define both theories. The Maximum Shear Stress Theory, also known as Tresca’s criterion, posits that yielding occurs when the maximum shear stress in a material reaches a critical value. This critical value is typically derived from the material’s yield strength in shear. Conversely, the Maximum Distortion Energy Theory, often referred to as von Mises criterion, contends that yielding results when the distortion energy in a material exceeds a critical threshold, regardless of the mode of loading. The distinction between these two theories is subtle yet significant.

To grasp whether one theory is more conservative than the other, it is vital to consider their underlying assumptions, practical applications, and consequences. The Maximum Shear Stress Theory is widely regarded as a simpler criterion, primarily because it necessitates fewer calculations. By focusing on shear stress alone, it provides a straightforward approach for engineers. However, its simplicity results in a somewhat limited applicability. It tends to be less effective for ductile materials under multi-axial states of stress, where it may underestimate the failure risk.

On the other hand, the Maximum Distortion Energy Theory accounts for a more comprehensive range of stress states. It incorporates the effects of both shear and normal stresses, delivering a more nuanced analysis of how materials deform and ultimately fail. As a result, many engineers and designers favor this criterion for its robustness, particularly in complex material behaviors. This thoroughness may suggest a conservatism, as it promotes safer designs by accounting for additional stress interactions. However, this complexity may require more intricate modeling and a stronger understanding of the material characteristics.

When comparing the two theories, it is critical to analyze specific scenarios. Consider a scenario where a ductile material is subjected to proportional loading. Under uniaxial loading conditions, both theories yield similar results. However, in scenarios where multi-axial loading is present, the Maximum Distortion Energy Theory may be deemed more conservative. This is particularly evident when dealing with materials that exhibit significant plastic deformation capabilities. In these instances, relying solely on shear stress as a metric could lead to unsafe designs.

Furthermore, the applicability of these theories extends beyond simple compressive and tensile loads. Their implications resonate across various engineering fields, including aerospace, civil, and mechanical engineering. For instance, in the aerospace industry, where materials must withstand extreme conditions, understanding both theories can significantly impact safety margins and overall design integrity. In these high-stakes environments, a more conservative approach that accounts for potential distortions—rather than merely shear stress—can prove invaluable in safeguarding against catastrophic failures.

Additionally, environmental factors come into play when evaluating the conservatism of each theory. In contemporary engineering practices, sustainability and material conservation are increasingly important. The Maximum Distortion Energy Theory’s more extensive assessment of material behavior may lead to optimized designs that utilize less material while ensuring safety. In contrast, designs based solely on Maximum Shear Stress might be larger and heavier, thus contributing to excess material consumption and subsequent environmental impacts. Hence, from a conservation perspective, the von Mises criterion could be regarded as more prudent and forward-thinking.

Moreover, the implications of using either theory extend to computational modeling and simulation, where advancements in technology allow for a more profound analysis of complex systems. Computer-aided design (CAD) and finite element analysis (FEA) tools have revolutionized how engineers can evaluate stress and strain, making it easier to apply the Maximum Distortion Energy Theory in practical applications. These tools can simulate the myriad loading scenarios that real-world materials face, offering detailed insights into potential points of failure that the Maximum Shear Stress Theory might overlook.

In conclusion, the question of whether Maximum Shear Stress Theory is more conservative than Maximum Distortion Energy Theory is nuanced and severely context-dependent. While the Maximum Shear Stress Theory may provide a simplified, quicker evaluation, it risks underestimating the complexities of material behavior, especially under multi-axial stress conditions. On the other hand, the Maximum Distortion Energy Theory, with its comprehensive approach, offers a more conservative and safer framework for design, particularly in applications involving ductile materials where deformation is prominent. As engineering increasingly incorporates sustainability and material conservation into its ethos, the latter theory, with its potential for optimized material usage and failure prediction, stands out as a more favorable choice.

Consequently, engineers must continually assess the merits of each theory in relation to their specific applications, striking a balance between simplicity, accuracy, and environmental responsibility.