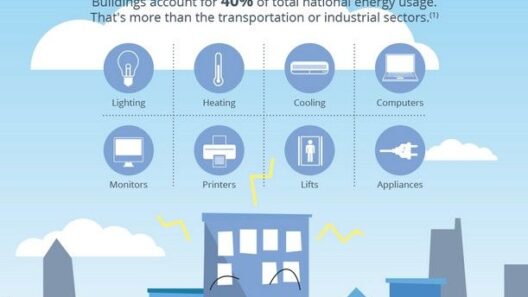

Energy conservation in steam systems is an imperative yet often overlooked aspect of engineering. Particularly in industrial settings, where steam systems account for a significant share of energy consumption, optimizing these systems provides an immediate pathway to improved energy efficiency. This paper discusses key elements of project implementation focused on steam system energy conservation. It elucidates various strategies, operational insights, and advanced technologies that can substantially mitigate energy waste.

Steam systems involve a complex interplay of components including boilers, steam lines, condensate return systems, and heat exchangers. Each component has its own role but collectively they represent both opportunities for improvement and challenges in energy management. Understanding the thermodynamic principles that govern steam generation and distribution is crucial. Higher quality steam delivered at optimal pressure and temperature enhances operational efficiency, while losses in heat through improper insulation, leaks, or inefficiencies in operation importantly detract from overall system performance.

Identifying energy losses is the first critical step in energy conservation projects. Conducting a comprehensive audit of the steam system facilitates the discovery of inefficiencies. This should include analyzing steam traps, inspecting condensate return rates, and measuring heat losses from distribution pipelines. Commonly, steam traps are a significant source of energy loss if they fail. A malfunctioning steam trap can lead to substantial blow-through, allowing steam to escape into the atmosphere without contributing to any productive work. By implementing data logging tools, engineers can monitor these components and evaluate system performance metrics over time, allowing for better predictive maintenance strategies.

In addition to auditing, engineers need to conceptualize energy recovery opportunities within the steam system. Consider the implementation of a condensate recovery system. Reusing condensate not only provides savings on water and energy required for boiler feed but greatly enhances overall system efficiency. The condensate should be returned to the boiler at as close to the boiling point as possible, minimizing the need for additional energy input to heat the water. Identifying potential points of heat recovery from other process systems—and integrating them into the steam framework—can further contribute to energy conservation efforts.

In parallel, enhancing the thermal efficiency of boilers is critical. Modern high-efficiency boilers can significantly reduce the energy consumed during steam generation. This includes retrofitting older boiler systems to improve their efficiency ratings, adopting advanced control systems, and ensuring that boiler operations are cycling efficiently rather than idling unnecessarily. By transitioning to technology that supports greater combustion efficiency, including oxygen trim controls and sophisticated combustion optimization software, substantial gains in operational efficiency can be achieved.

Incorporate strategies to manage and reduce steam leakage within the distribution network. Steam leaks can waste a remarkable amount of energy, making regular maintenance paramount. Insulation of pipes and fittings is another elementary yet effective tactic—reducing heat loss during steam transmission conserves energy that would otherwise contribute to reheating demand. The use of updated insulation materials also often pays back quickly due to the low-cost returns associated with energy savings over time.

Operational strategies must not be overlooked as well. User training and implementation of best practices plays a vital role. Often, personnel involved in the operation of steam systems may lack awareness regarding the implications of system inefficiencies and the environment. Enlightening operators on the importance of monitoring energy usage, encouraging best maintenance practices, and promoting continuous improvement initiatives can lead to a culture of energy conservation within an organization.

Furthermore, periodic reviews of system performance should be conducted. Establishing Key Performance Indicators (KPIs) specific to steam systems allows for benchmarking against industry standards. These KPIs can include measurements of steam quality, system efficiency ratios, and energy consumption against production levels. Using these indicators, organizations can create actionable insights to identify trends and areas for improvement.

Advanced technological solutions such as predictive analytics and automation systems also present opportunities for the modern engineer focused on steam system energy conservation. Implementing Internet of Things (IoT) technology can facilitate real-time monitoring and data collection across the steam network. Such digitization enables predictive maintenance schedules which can prevent costly downtimes and improve the reliability of the system. Integrated management systems can analyze this data, leading to proactive adjustments in system operations that fine-tune energy usage.

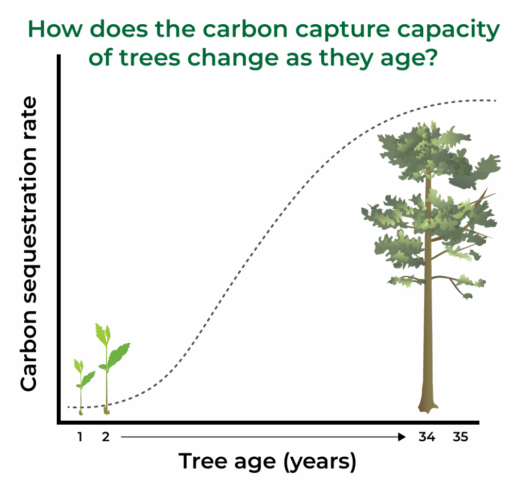

A commitment to environmental stewardship is indispensable in the discourse surrounding steam system efficiency. By reducing reliance on fossil fuels and lowering emissions through optimized steam systems, engineers contribute to a broader agenda of sustainability. Within this framework, adhering to national and international standards for energy efficiency provides an additional layer of accountability that advances energy conservation initiatives.

Ultimately, steam system energy conservation transcends mere financial prudence; it aligns with the global shift towards sustainable engineering practices. The combined efforts of engineers to implement rigorous auditing, advanced technologies, robust operational practices, and a clear commitment to continuous improvement pave the way for significant energy savings. As the complexities of energy systems evolve, so too must the approaches that engineering professionals employ. Collectively, these actions herald a future marked by efficient, sustainable energy management that benefits not only individual organizations but also the broader environment.