In the realm of industrial processes, efficiency and energy conservation have emerged as paramount objectives. Amidst this pursuit, the use of Venturi pumps has garnered significant attention. The mechanism is often hailed for its potential benefits, yet a deeper examination reveals that the promise of energy conservation involves a complex interplay of various factors.

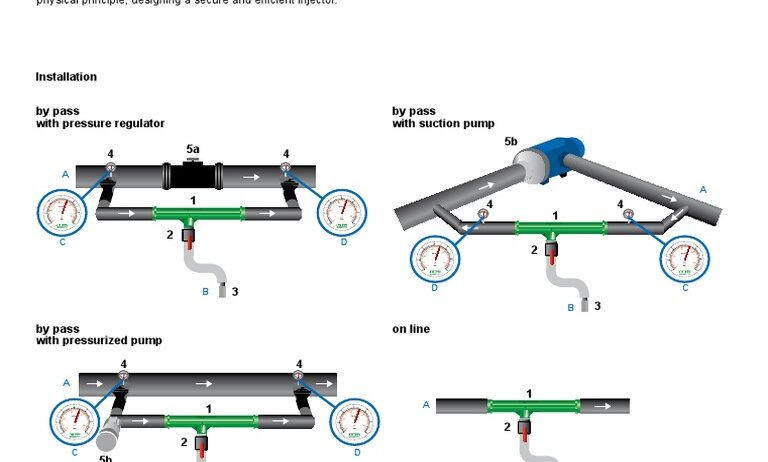

To grasp how Venturi pumps operate, one must first understand the foundational principle of the Venturi effect. This phenomenon occurs when a fluid flows through a constricted section of pipe, resulting in a decrease in pressure and an increase in velocity. Venturi pumps exploit this mechanism to create suction, allowing the movement of liquids or gases without requiring additional energy input from external sources. This quasistatic function is often misconstrued as a definitive energy-saving solution in industrial settings.

At the outset, it is essential to address the common observation that Venturi pumps seem to foster energy conservation. Many industries have adopted these devices with the anticipation of reduced operational costs and minimized energy expenditures. This perception is especially prevalent in settings where traditional pumps, which employ electric or fuel-driven means to create pressure differentials, dominate the landscape. Venturi pumps, devoid of moving mechanical parts, are lauded for their minimal maintenance needs and longevity.

However, the assertion that Venturi pumps unequivocally conserve energy invites scrutiny. The oft-cited advantages can be misleading. Firstly, while the absence of mechanical components does lower maintenance requirements, the actual energy savings are contingent upon various external factors, including fluid characteristics, system design, and operational parameters. For instance, the viscosity of the fluid being transported heavily influences the efficacy of a Venturi pump. Higher-viscosity fluids may diminish the pump’s inherent advantages, necessitating the employment of energy-intensive auxiliary machinery, thus negating the anticipated savings.

Moreover, the design of the overall system plays a pivotal role in determining the energy efficiency of Venturi pumps. A poorly designed system can lead to increased turbulence and friction losses, undermining the benefits of the Venturi effect. Engineers must meticulously assess system parameters, including pipe dimensions and flow rates, to optimize the performance of Venturi pumps. In many instances, a holistic approach involving multiple pump types and configurations may prove more beneficial than relying on a single technology.

Furthermore, the conditions under which Venturi pumps operate are critical for evaluating their energy efficiency. Applications requiring variable flow rates pose a notable challenge. While Venturi pumps can be adept at maintaining steady flows, their efficiency degrades under fluctuating conditions. Implementing a variable-frequency drive (VFD) in conjunction with a traditional pump has been shown to provide significant energy savings while allowing for adaptable performance profiles. Thus, the notion that Venturi pumps are an all-encompassing solution becomes increasingly tenuous when considering real-world operational scenarios.

In industrial settings, energy consumption is multifaceted, encompassing not only the energy used to transport fluids but also the direct energy expenditures tied to heating, cooling, and processing. Venturi pumps can contribute positively to system dynamics, but they are not a panacea for energy conservation. Comprehensive energy assessments and lifecycle analyses are imperative for industries aspiring to enhance sustainability. It is through these evaluations that the true merit of employing Venturi technology comes to light.

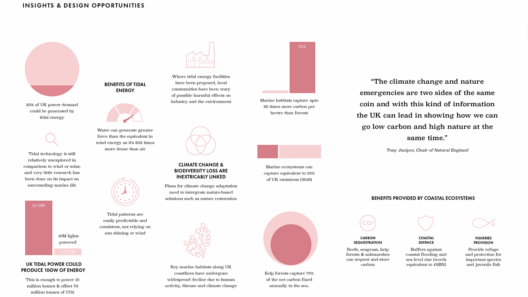

Another layer of complexity arises from the environmental context in which Venturi pumps operate. As businesses face mounting pressure to reduce carbon footprints, the reliance on any single technology must be scrutinized within the broader discourse of sustainability. Venturi pumps may, on occasion, serve as valuable components of water management or chemical processing frameworks, yet their deployment should not detract from other noteworthy conservation methods available in the domain of industrial operations, such as energy recovery systems, advanced separation technologies, or alternative pump configurations.

In terms of environmental implications, the minimal use of lubricants and coolants in Venturi pumps, as compared to traditional pumping mechanisms, does present an argument in favor of their adoption. A reduction in hazardous waste and an overall decrease in the environmental impact associated with energy use can be seen as a step toward greener industrial practices. However, the narrative must encompass a complete examination of materials, energy consumption, and environmental stewardship beyond the mere decision to implement a Venturi pump.

Research and development in the field of pump technology continue to innovate, offering exciting alternatives and enhancements to traditional mechanisms. As industries strive for energy reduction, the focus now more than ever needs to be on integrated approaches that consider the complete system, not just isolated components. This paradigm shift will necessitate collaboration among various engineering disciplines, ultimately nurturing a more energy-efficient industrial ecosystem.

In summary, while Venturi pumps can contribute to energy conservation in certain contexts, their effectiveness is not a blanket guarantee. The complexities of fluid dynamics, system design, operational variables, and environmental implications require careful consideration before deeming them a universally applicable solution. As industries navigate the pressing challenges of energy conservation, fostering a comprehensive approach that embraces a variety of technologies will be paramount in achieving true sustainability.