In the contemporary landscape of industrialization, the perplexing relationship between massive factories and climate change has garnered significant attention. This phenomenon is not incidental; rather, it epitomizes a pervasive concern regarding the ecological consequences of unfettered manufacturing. Giant factories, often characterized by their colossal dimensions and high-output capabilities, serve as both the engines of economic growth and the vanguards of environmental degradation. Their operations engender multifaceted impacts that exacerbate climate change, invoking a critical examination of the practices that drive these behemoths.

The primary mechanism through which giant factories contribute to climate change is the prodigious emission of greenhouse gases (GHGs). These establishments, reliant on fossil fuels for energy, release copious amounts of carbon dioxide (CO2), methane (CH4), and other deleterious gases into the atmosphere. The combustion of coal, oil, and natural gas during manufacturing processes leads to a significant carbon footprint. For instance, cement production, an essential component of construction, alone accounts for nearly 8% of global CO2 emissions. Such emissions destabilize the planet’s climate system, leading to increased temperatures, rising sea levels, and severe weather events.

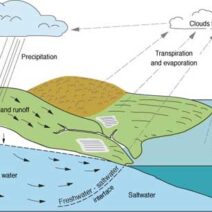

Moreover, the operation of giant factories often entails the consumption of vast quantities of water and other natural resources. The extraction and processing of raw materials create a ripple effect that exacerbates ecological degradation. For example, the industrial agricultural sector, which operates on a monumental scale, not only contributes to deforestation but also results in soil depletion and water scarcity. These practices further influence climate change by disrupting local ecosystems, diminishing biodiversity, and releasing additional GHGs trapped in natural carbon sinks like forests and wetlands.

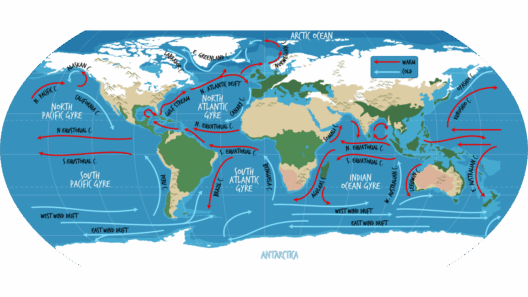

Additionally, the transport of materials and products across lengthy supply chains significantly amplifies the carbon impact of industrial operations. The globalization of manufacturing has led to intricate networks wherein goods are sourced from various locations and transported worldwide. This logistics dance, often reliant on fossil fuel-powered vehicles, contributes substantially to the carbon emissions associated with the lifecycle of products. The water and air transport sectors are particularly notorious for their emissions, often escaping stringent regulatory oversight.

The internal structure of giant factories further exacerbates their adverse impact on the environment. Many facilities prioritize production efficiency over sustainable practices, resulting in high energy consumption and waste generation. The phenomenon of planned obsolescence — a strategy employed by certain industries to reduce the lifespan of products — ensures continuous demand and shapes consumer behavior. The inevitable disposal of these products leads to landfills filled with non-biodegradable materials, releasing methane, a potent GHG, as they decompose.

Not to be overlooked is the socio-political dimension entwined with these colossal factories. Industrial powerhouses wield significant influence over policy-making, often lobbying against regulations that would mitigate their environmental impact. In many cases, companies prioritize short-term profits, neglecting long-term ecological stewardship. This dynamic creates a systemic inertia, where regulation remains superficial, perpetuating a cycle of environmental harm. Without stringent regulations and incentives for sustainability, the trajectory of climate change remains steeply upward.

While the challenges posed by giant factories are daunting, innovative solutions have emerged highlighting the potential for a transformation in industrial practices. The implementation of cleaner technologies and alternative energy sources presents a pathway for factories to reduce their carbon footprints. Utilizing renewable sources such as solar or wind power, and integrating energy-efficient machinery can significantly diminish emissions. Furthermore, factories can adopt circular economy principles that focus on recycling materials, reducing waste, and enhancing product lifespan.

Transitioning towards sustainable practices in manufacturing is not merely an option; it is an imperative for combating climate change. Employing life cycle assessments (LCAs) allows organizations to evaluate the environmental impact of their products comprehensively, fostering an ethos of responsibility. Innovations such as carbon capture and storage (CCS) technologies are also being explored, presenting potential avenues for mitigating emissions from industrial sources. Collaboration among stakeholders, including governments, corporations, and civil society, is crucial in catalyzing this shift.

The consumer landscape also plays a pivotal role in shaping corporate behaviors. Increased awareness regarding the environmental impacts of giant factories has spurred a demand for sustainable products. Consumers are becoming more discerning, favoring brands that commit to sustainable practices and transparency. This shift holds the potential to prompt companies to reevaluate their operational strategies and invest in green technologies to retain market relevance.

In conclusion, the intricate relationship between giant factories and climate change underlines a broader narrative about our industrialized society. It is imperative to recognize that the actions of these industry titans reverberate far beyond their immediate surroundings, influencing global climate systems. Addressing this challenge requires a multifaceted approach that encompasses regulatory reforms, technological innovation, and consumer advocacy. Fostering a paradigm shift towards sustainability within manufacturing is not merely an environmental imperative but a fundamental necessity for the survival of future generations. The time for action is now, as the consequences of inaction loom palpable on the horizon.