Energy conservation is a fundamental principle of physics that serves as the cornerstone for understanding how machines operate efficiently. At its core, the conservation of energy posits that energy cannot be created or destroyed; rather, it can only be transformed from one form to another. This principle holds profound implications for machines and their efficiency in converting energy from one form into useful work.

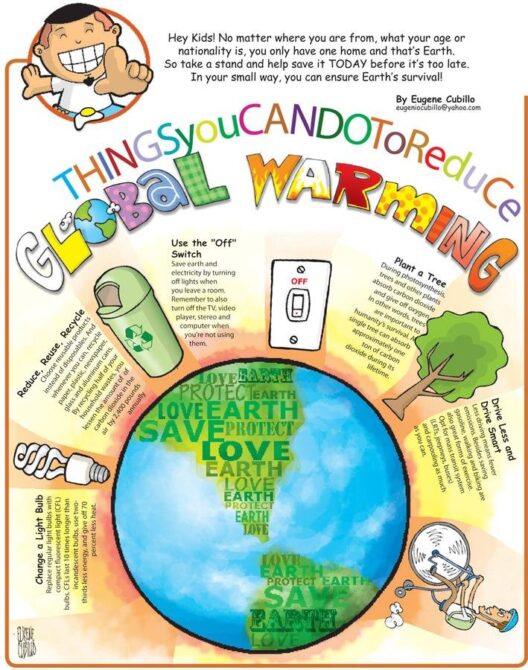

Machines are ubiquitous in modern life, ranging from simple levers and pulleys to complex systems like internal combustion engines and electric generators. Each of these machines epitomizes the transformation of energy, whether it be from mechanical, thermal, chemical, or electrical sources. Understanding how energy conservation applies to machines is critical for optimizing their performance and, ultimately, for addressing broader environmental concerns such as energy consumption and greenhouse gas emissions.

Types of Energy Transformation in Machines

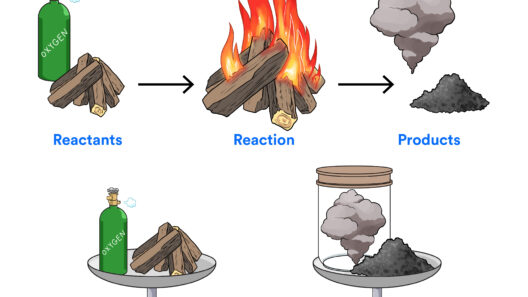

Machines leverage various forms of energy, each necessitating a distinct conversion process to achieve mechanical work. For example, an internal combustion engine converts the chemical energy stored in fuel into thermal energy through combustion, which is then transformed into mechanical energy as the engine’s pistons move. In contrast, electric motors transform electrical energy into mechanical energy with comparatively higher efficiency, minimizing wastage.

Consider the case of a hydraulic lift, which employs hydraulic fluid’s potential energy to elevate heavy loads. The efficiency of such machines relies heavily on minimizing energy losses, whether through friction, heat dissipation, or other forms of resistance. The key lies in understanding the energy flow within the machine and identifying opportunities for improving this flow.

Mechanical Efficiency and Losses

Mechanical efficiency is a measure of how effectively a machine converts input energy into output work. It is mathematically defined as the ratio of useful work output to the total energy input. In an ideal scenario where no energy is lost, this efficiency would be 100%. However, in reality, machines experience various forms of energy losses, primarily due to friction, heat, and sound. These losses directly impact the overall efficiency and performance of machines.

Friction, a ubiquitous force in machinery, acts as a principal impediment to efficiency. When components of a machine move against each other, energy is dissipated as heat due to frictional forces. Lubricants are often employed to mitigate this loss by reducing the interaction between moving surfaces, thus enhancing the machine’s overall efficiency.

Moreover, heat losses occur inevitably during energy conversion processes. For example, in an automobile engine, a significant portion of the chemical energy in fuel is lost as heat to the exhaust and cooling systems. Improving thermal efficiency—by utilizing advanced materials or designs—can lead to enhanced overall performance. Exploring alternative fuels with higher energy content and lower emissions may also drive efficiency improvements in combustion engines.

Sound energy, while often overlooked, is another form of waste energy. Machines such as generators and pumps frequently operate noisily, indicating energy being lost in the form of sound. This not only contributes to decreased efficiency but can also have adverse environmental and health impacts.

Innovations in Energy Efficiency

Innovation plays a pivotal role in enhancing the energy efficiency of machines. Modern advancements in material science, engineering design, and automation technology can lead to significant improvements. For instance, the development of composite materials reduces the weight of components while maintaining structural integrity, thus lowering the energy required for operation.

Furthermore, the advent of smart technologies and the Internet of Things (IoT) allows for real-time monitoring and analysis of machine performance. By gathering data on energy use and operational parameters, operators can identify inefficiencies and make informed decisions to optimize systems dynamically. Predictive maintenance, powered by AI algorithms, can preemptively address potential failures, thereby ensuring machines operate at peak efficiency.

Renewable Energy Integration

With the rising urgency of climate change, the integration of renewable energy sources into machinery can also bolster sustainability efforts. Solar panels, wind turbines, and bioenergy systems can complement traditional machines, thereby reducing reliance on fossil fuels. For example, combining solar energy with electric vehicles not only enhances energy efficiency but also minimizes environmental impacts. Such hybrid systems epitomize the future of efficient energy utilization while championing the fight against climate change.

Lifecycle Impact and Sustainability

Assessing energy efficiency in machines extends beyond operational performance to encompass their entire lifecycle—from design and manufacturing to usage and disposal. Sustainability principles advocate for minimizing resource extraction and waste generation throughout a machine’s lifecycle. By adopting a circular economy approach, manufacturers can prioritize designs that enable easier disassembly and recycling of components, thus conserving energy and materials.

Furthermore, public policies and incentives aimed at encouraging energy-efficient machines can significantly influence market trends. By promoting eco-friendly technologies and practices, governments can drive manufacturers towards higher efficiency standards, ultimately reducing the collective carbon footprint of industrial operations.

Conclusion

The conservation of energy in machines is a multifaceted consideration that encompasses a spectrum of energy transformations and efficiencies. By understanding the mechanisms of energy flow and loss, embracing innovation, and prioritizing sustainability, it is possible to optimize machine performance while mitigating negative environmental impacts. As society stands at the nexus of technological advancement and climate urgency, the critical examination of how machines utilize and conserve energy will play a pivotal role in shaping a more sustainable future.