The conservation of energy in a mechanical system is a foundational principle that describes how energy is transformed and transferred in physical systems while remaining constant in total quantity. In essence, energy cannot be created or destroyed; it can only change forms. This principle is crucial in understanding the workings of various machines and mechanical systems we encounter in our daily lives, from simple devices to complex machinery.

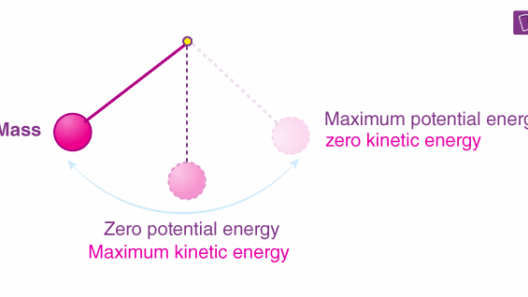

The primary components of a mechanical system include kinetic energy, potential energy, and the forces acting upon these energies. Kinetic energy is the energy possessed by an object due to its motion, governed by the equation KE = 1/2 mv², where m is mass and v is velocity. Conversely, potential energy, often associated with an object’s position or configuration, is best exemplified by gravitational potential energy, calculated using the formula PE = mgh, where h is height above a reference point and g is gravitational acceleration. Understanding these two energy forms is crucial for dissecting how mechanisms operate.

In classical mechanics, the law of conservation of mechanical energy asserts that the total mechanical energy of a system (the sum of kinetic and potential energy) remains constant if only conservative forces (such as gravity) are acting on it. This principle elucidates events such as a pendulum swinging back and forth: at its highest points, the pendulum possesses maximum potential energy and negligible kinetic energy; conversely, at its lowest point, the potential energy is minimal, while kinetic energy is at its peak. Here, energy seamlessly interchanges between kinetic and potential forms, demonstrating the conservation principle in action.

Consider the concept of friction, which introduces non-conservative forces into mechanical systems. Friction converts mechanical energy into thermal energy through heat, leading to a loss of usable mechanical energy. In practical applications, this phenomenon highlights the importance of lubrication in machines, which minimizes energy dissipation and enhances efficiency. Engineers strive to design systems that either minimize friction or harness it effectively—for instance, in brakes that intentionally convert kinetic energy into heat, ensuring the safety of vehicles.

Another salient aspect of mechanical systems is their configuration and design. The efficiency of energy conversion is often dictated by the geometric and material choices made during the design phase. For example, gears, levers, and pulleys exploit mechanical advantage, allowing small inputs of energy to produce larger outputs through the strategic redistribution of forces. This mechanical advantage is inherently linked to the conservation of energy, as these systems optimize the transformation of energy forms within the constraints of the mechanical environment.

Let us delve deeper into specific examples of mechanical systems that exemplify the principles of energy conservation. The simple machine known as the lever exemplifies how small input forces can yield significant output forces by redistributing energy effectively. The lever operates on the principle of moments, where the product of the force and distance from the pivot point remains constant, illustrating the conservation of energy through force multiplication.

In the realm of engineering applications, automobiles serve as a quintessential example where energy conservation principles manifest vividly. The internal combustion engine converts chemical energy from fuel into mechanical energy. As the engine operates, the laws of energy conservation govern the transformation of energy, with kinetic energy propelling the vehicle and potential energy stored in different components, such as in the suspension system. The design efficiency of these vehicles hinges on minimizing energy losses—through emissions control, efficient fuel use, and power transmissions—reflecting the intense focus on energy conservation in the automotive industry.

Wind turbines present another compelling case where energy conservation is pivotal. In converting kinetic energy from wind into electrical energy, these systems underscore the interplay between kinetic energy conservation and its transformation into another useful form. The blades of the turbine capture wind’s kinetic energy, rotating the generator’s rotor, which produces electricity. This conversion process illustrates how energy can be conserved through innovative designs that optimize the extraction of energy from natural resources.

Moreover, the advancement of renewable energy technologies is revolutionizing our approach to mechanical systems. As society shifts towards sustainable practices, understanding energy conservation becomes more critical. Energy-harvesting technologies like piezoelectric devices capture mechanical energy from human actions, such as walking, to power small devices. These innovations demonstrate how energy conservation principles can promote sustainability while simultaneously addressing energy demands.

Understanding the intricacies of mechanical systems is vital as we navigate a rapidly advancing technological landscape. As we hone our comprehension of energy conservation, we can better design and operate machines that not only function efficiently but also contribute to reducing our carbon footprint. Consequently, the sustainable integration of energy conservation principles into engineering practices emerges as a clarion call for the next generation of innovators.

In conclusion, the conservation of energy in mechanical systems is a fundamental concept that underpins our interaction with the physical world. By understanding how kinetic and potential energy interrelate, and by exploring the ramifications of dissipative forces like friction, we gain insights into optimizing efficiency in various applications. As technology evolves and the push for sustainability intensifies, the principles governing energy conservation provide a valuable framework for developing efficient systems that balance human needs with environmental responsibility.