The intricate dance of mechanics often reveals itself in the guise of simple tools. Among these, the pulley system stands out as a marvel of engineering ingenuity, akin to a balletic performance where each participant plays a vital role in executing a seamless lift. In a world where energy conservation has become a pressing imperative, understanding how energy is conserved in pulley systems, especially when lifting loads, is crucial. This exploration unveils not just the mechanics but also the profound implications for our efforts to mitigate climate change.

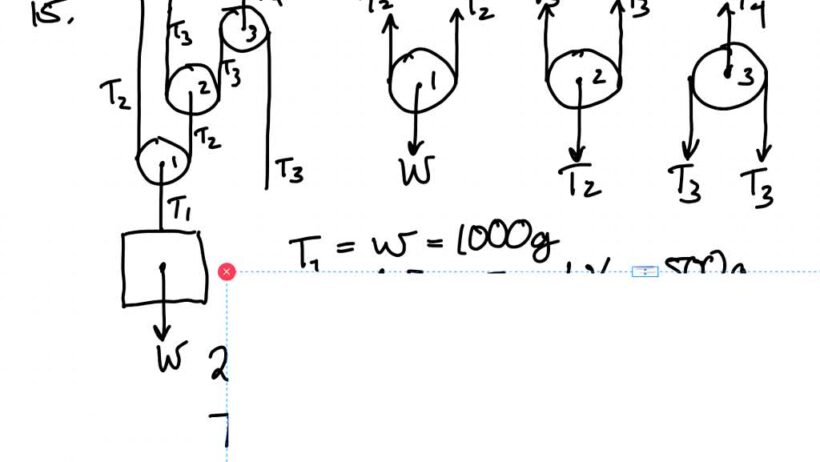

At its core, a pulley system is a device that employs one or more wheels and a rope to facilitate the lifting of heavy objects. Imagine pulling a stubborn friend up a steep hill with minimal effort; a pulley transitions that strenuous task into a manageable one. This mechanism allows individuals to apply a smaller force over a longer distance, effectively trading distance for effort. The fundamental principle here is based on the conservation of energy, which states that energy cannot be created or destroyed but can only be transformed from one form to another.

When a load is lifted using a pulley system, the energy input is converted into gravitational potential energy. As the rope is pulled down, the load rises up. The pulley’s role is akin to a skilled trader, efficiently exchanging substantial effort for notable results. The ideal scenario assumes negligible friction and perfectly efficient systems, allowing the energy expended to equal the energy used to lift the object. However, in realistic applications, energy losses generally occur due to friction in the system and the weight of the ropes and pulleys themselves. This is where the intriguing concept of efficiency blossoms, defining how well a system can convert input energy to useful work.

To delve deeper, consider the configuration of various pulley systems—simple, compound, and block and tackle. A simple pulley consists of a single wheel and offers a mechanical advantage of 1, meaning it allows one to redirect the force but doesn’t reduce the amount of effort needed. A compound pulley, however, combines multiple wheels, enabling a more pronounced mechanical advantage. This configuration exemplifies the idea of leverage, where a smaller input force can generate a larger output force. It functions similarly to how extensive environmental advocacy can amplify individual voices into a unified call for action.

In a block and tackle system, numerous pulleys work in tandem, significantly enhancing efficiency. It is within this intricate framework that the beauty of energy conservation truly shines. For example, with a block and tackle setup, a worker may lift a load that is ten times heavier than the force they must exert, manifesting an exhilarating display of physics at work. Inputting energy in this manner allows for sustainable practices, limiting the exertion necessary and conserving physical energy. For environmental activists, this representation of mechanical efficiency echoes the ethos of reducing waste and optimizing resource use, both of which are pivotal in combating climate change.

Moreover, the energy conservation principle in pulleys can be illustrated through the lens of renewable energy initiatives. Wind turbines, for instance, can be viewed as a modern interpretation of the pulley—capturing kinetic energy from moving air and converting it into usable electricity. Just as pulleys transform our physical efforts into achievable lifts, renewable energy systems transform natural forces into sustainable power, presenting a seamless connection between age-old mechanics and contemporary environmental considerations.

While exploring these mechanical wonders, one must not overlook the role of friction. Indeed, friction is the uninvited guest at the party of efficiency, subtly sapping away energy that could otherwise be harnessed. As the rope moves over the wheel, friction generates heat and resists motion, highlighting the importance of maintaining well-lubricated systems. In much the same vein, our efforts to create a sustainable world often face friction in the forms of resistance to change and systemic inertia. To overcome these challenges requires innovation, research, and a willingness to advance towards a greener future.

For engineers and designers, enhancing the efficiency of pulley systems entails meticulous attention to material properties, the shape of the pulleys, and the characteristics of the ropes. Each choice can mitigate frictional losses and improve the conservation of energy. Lightweight materials and low-friction bearings are continually developed, transforming the basic principles of pulleys into high-performance systems adept at conserving energy more effectively. This mirrors the advancements in sustainable technology aimed at maximizing output while minimizing ecological footprints.

In conclusion, pulley systems epitomize the marvel of energy conservation, where minimal effort can yield substantial results. They serve as a metaphor for our potential to achieve significant environmental progress by embracing innovative practices, leveraging technology, and working collectively to optimize resource use. As we venture further into an era where climate change looms large, understanding and applying the principles embodied in these systems may well light the path toward sustainable living. The coordination of energy, mechanics, and environmental stewardship forms a compelling narrative that beckons us to consider our role within the larger fabric of the universe, where each small action contributes to the monumental changes necessary for a better, greener world.