Energy conservation principles are fundamental to understanding various physical systems. However, integrating concepts such as rolling friction into these calculations requires a nuanced perspective that can yield intriguing insights. This compendium delves into the intricacies of incorporating rolling friction into conservation of energy models, elucidating its significance along the way.

At the core of conservation of energy, we acknowledge that the total energy in a closed system remains constant. This theorem persists unscathed through myriad physical interactions, such as kinetic energy, potential energy, and thermal energy transformations. Rolling friction, a subtle but crucial player in this interplay, merits exploration. Unlike sliding friction, which decelerates motion through direct resistance, rolling friction arises from deformation and is inherently less intense. Nonetheless, its effects are far-reaching.

To begin, it is essential to comprehend the definition of rolling friction. Rolling friction refers to the resistance that occurs when an object rolls over a surface. It is contingent upon various factors, including the nature of the surfaces in contact, the shape and material of the rolling object, and external forces acting upon it. This resistance, though often lesser than sliding friction, can still significantly impact the energy dynamics of a system.

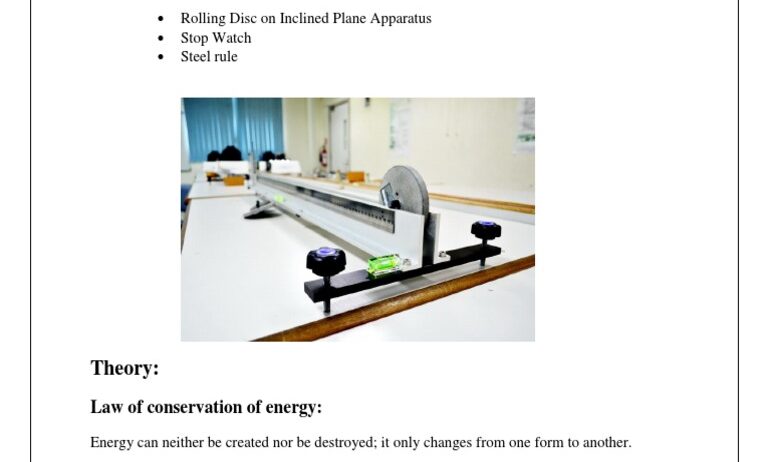

In a practical scenario, envision a disc rolling down an inclined plane. As it descends, it is propelled by gravitational potential energy. The mechanical energy conversion transpires seamlessly, transitioning from potential energy at the peak to a combination of kinetic energy as translational and rotational forms at the base. Yet, the imposition of rolling friction introduces a layer of complexity that requires careful accounting.

When calculating the rolling friction, we employ the equation:

D = μr N

where D represents the rolling friction force, μr stands for the coefficient of rolling friction, and N signifies the normal force. It is imperative to gauge both the coefficient of rolling friction and the normal force accurately, as these parameters significantly influence the calculations. The coefficient varies depending on the materials involved; typical values may range from 0.001 to 0.01 for rubber on asphalt, illustrating the variance based on conditions.

Next, we must integrate this rolling friction into the conservation of energy equation, which typically reads:

Einitial = Efinal

In the presence of rolling friction, this equation becomes:

Epotential – Wfriction = Ekinetic

In this paradigm, Wfriction embodies the work done against rolling friction, calculated as:

Wfriction = D * d

Here, d denotes the distance traveled by the disc. Adequately substituting these variables allows for a comprehensive understanding of energy loss due to rolling resistance.

Consider the impact of neglecting rolling friction in calculations. In doing so, one may overestimate the energy available for motion, leading to miscalculations in real-world applications such as vehicle dynamics, sports physics, and even rolling machinery design. For instance, automotive engineers must consider rolling friction to optimize fuel efficiency and performance, ensuring that their designs accommodate these energy losses while advancing toward sustainability.

Explorations into rolling friction’s implications extend to diverse fields. For instance, in the domain of environmental science, recognizing how rolling friction affects the motion of sediment in river systems allows for more accurate modeling of erosion and transportation. These models assist in understanding ecological impacts and guiding conservation efforts.

Indeed, awareness of rolling friction’s role necessitates a cognitive shift in how we approach energy conservation. Traditionally viewed as an ancillary component, rolling friction emerges as a significant factor in energy loss, urging physicists, engineers, and environmental scientists alike to readjust analytical frameworks. This burgeoning understanding fosters innovation—new materials and designs aimed at minimizing friction can lead to advancements in energy-efficient technologies. Additionally, this builds synergy between engineering practices and environmental sustainability goals.

Discussions surrounding rolling friction invariably touch upon future possibilities. As researchers continue to explore new materials and coatings, the potential for reducing rolling friction while enhancing durability becomes tantalizing. Innovations such as advanced composites and surface treatments could pave the way for enhanced energy efficiency across myriad applications, from transportation to manufacturing.

Ultimately, recognizing the role of rolling friction involves a paradigm shift, compelling stakeholders from various sectors to adopt fresh perspectives in energy conservation strategies. The subtle complexities embedded within this phenomenon promise intriguing avenues for exploration. Industry professionals equipped with this knowledge can drive change, fostering an environment conducive to sustainable advancements. Thus, understanding rolling friction is not merely an academic exercise; it is a call to action for innovation, interdisciplinary collaboration, and environmentally conscious engineering practices.

The nexus of rolling friction and conservation of energy stretches far beyond theoretical calculations. It invites curiosity, underscores systemic interconnections, and emphasizes the necessity for diligence in energy management. Through a concerted effort to integrate rolling friction into energy assessments, stakeholders across sectors will chart pathways towards optimizing efficiency and fostering environmental stewardship, ultimately rendering a more sustainable future.