Is energy conserved in trucks? This playful question invites us to examine the intricate mechanisms at play within these heavy-duty vehicles that form the backbone of logistics and transportation. The trucking industry is essential; however, its implications for energy consumption and environmental impact are monumental. In exploring whether energy is conserved in trucks, we traverse a landscape rife with challenges, including the sustainability of fuel sources, advancements in technology, and the virtues of vehicle design.

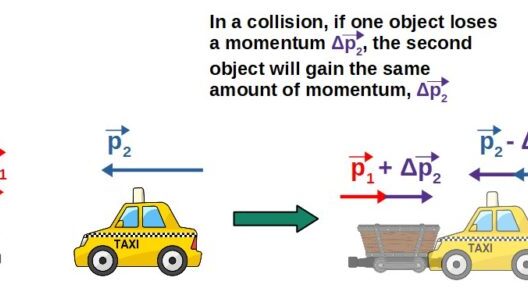

The question of energy conservation centers around the fundamental laws of physics. Specifically, the First Law of Thermodynamics, which states that energy cannot be created or destroyed, only transformed from one form to another. Trucks are designed to harness energy, converting fuels into mechanical energy that facilitates movement. But this transformation comes at a cost—inefficiencies are ubiquitous throughout the process. As we reflect on the numerous components involved—from the engine and drivetrain to the tires and aerodynamics—it’s evident that each element plays a pivotal role in dictating energy efficiency.

Trucks predominantly run on diesel or gasoline, although alternative energy sources are emerging with increasing frequency. The internal combustion engine (ICE) is the most common power source for trucks today. While reliable, ICEs have inherent limitations. They typically convert only about 20-30% of the energy in fuel into actual mechanical power—significant energy losses occur through exhaust emissions, heat dissipation, and friction among moving parts. As a result, one must ponder: how can we minimize these inefficiencies, and is it even feasible to achieve true energy conservation in such a system?

As a response to these inefficiencies, the trucking industry is evolving. Hybrid technologies are gaining traction, combining the benefits of internal combustion engines with electric drives. These vehicles often store kinetic energy during braking through regenerative braking systems, reusing that energy to power auxiliary systems or even aid in propulsion. However, the challenge lies in the lifecycle of the batteries themselves, as mining and manufacturing processes contribute to environmental degradation. Thus, the question arises: do the benefits associated with hybrid trucks outweigh their ecological imprint?

Aside from hybrid systems, the advent of fully electric trucks offers a paradigm shift in energy conservation. By eliminating the internal combustion engine altogether, electric trucks promise increased efficiency. Electric motors can achieve efficiencies upwards of 90%, and energy losses are greatly reduced. Yet, widespread adoption hinges on infrastructure and battery technology advancements—two hurdles that cannot be easily surmounted. Furthermore, energy sources used to charge electric trucks must also be examined. If they derive from fossil fuels, the environmental gains diminish significantly.

A critical aspect of energy conservation in trucks is aerodynamics. The design of a truck affects its drag coefficient, which in turn influences energy consumption. Manufacturers are increasingly employing wind-tunnel testing to optimize vehicle shapes, reduce turbulence, and improve fuel efficiency. Features such as side skirts, trailer tails, and rounded noses can significantly lower fuel consumption. But how do we incentivize trucking companies to embrace these cost-effective technologies? The challenge remains in balancing initial investment against long-term savings.

Moreover, we must consider the role of regulations and policies in shaping the energy landscape of trucking. Governments are imposing stricter emissions standards and fuel economy regulations, incentivizing the adoption of cleaner technologies. However, compliance costs can burden small operators, deterring innovation. A potential challenge lies in creating equitable frameworks that encourage widespread participation, ensuring that all players in the trucking ecosystem can transition toward sustainable practices.

Logistics optimization techniques can also contribute to energy conservation in trucks. Route planning software, which utilizes real-time traffic data and predictive analytics, can enhance route efficiency. By avoiding congestion and minimizing idle time, trucks consume less fuel and emit fewer greenhouse gases. Yet, this approach requires collaboration among carriers, shippers, and technology providers. The industry must rise to meet this challenge by fostering partnerships that prioritize sustainable practices across the supply chain.

Addressing the energy conservation question requires the integration of multiple disciplines, including engineering, policy-making, and environmental science. It necessitates a holistic evaluation of the entire trucking ecosystem and an acknowledgment that true energy conservation is not merely about the technology in trucks but also about our societal approach to transportation and logistics.

In closing, the pursuit of energy conservation in trucks embodies an intricate dance of mechanics and environmental stewardship. This relationship underscores the necessity for innovation, collaboration, and progressive regulation. The nuances of energy transformation in trucking challenge us to ponder: how can we work collectively to maximize efficiency while minimizing our carbon footprint? The stakes are high, and the journey towards sustainability in the trucking industry is only just beginning. Each step taken can transform mechanical power into a force for environmental good, one truck at a time.