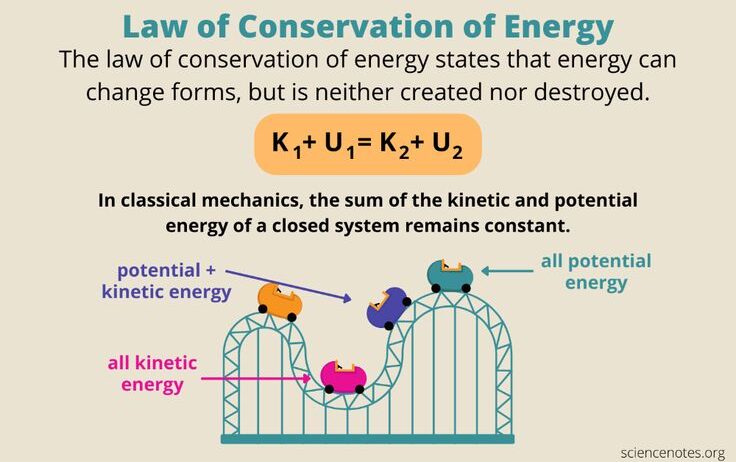

Mechanical energy conservation is a fundamental principle in physics, governing how energy transitions between kinetic and potential forms within a system. It is a focal point of study in various fields, from engineering to environmental science. The law of conservation of energy asserts that energy cannot be created or destroyed; it can only change forms. Nevertheless, multiple factors influence the efficiency and efficacy of mechanical energy conservation, including friction, energy dissipation, system design, and external forces.

At its core, mechanical energy entails two primary forms: kinetic energy, which is the energy of motion, and potential energy, which is stored energy based on the position of objects within a gravitational field or elastic systems. Understanding the dynamic interplay between these energy forms is essential for optimizing systems such as engines, machines, and even ecosystems. However, the reality is that not all mechanical energy remains conserved due to various factors that impede ideal mechanisms.

One significant factor affecting mechanical energy conservation is friction. Friction is the resistance that one surface or object encounters when moving over another. It is prevalent in machines, vehicles, and any system involving mechanical movement. While friction can be beneficial in some contexts, such as providing traction, it often results in energy loss in the form of heat. The transformation of mechanical energy into thermal energy diminishes the total mechanical energy available for useful work. Therefore, minimizing friction through lubrication, material selection, and advanced engineering techniques is crucial in enhancing energy conservation.

Moreover, the concept of energy dissipation cannot be overlooked. Energy dissipation occurs when mechanical energy is transformed into non-recoverable forms due to inelastic collisions or deformation of materials. For instance, when two objects collide, the kinetic energy may not completely convert back into potential energy post-collision. This loss is often due to sound, heat, or permanent deformation, which impedes the overall conservation of mechanical energy. Understanding the materials involved in these interactions can provide insights into how energy conservation can be bolstered.

The design of mechanical systems plays a critical role in energy conservation. Efficient system design can mitigate losses that arise from inefficiencies and technological constraints. For instance, optimizing the geometry of components can reduce drag and inertia, leading to enhanced kinetic energy conservation. In hydraulics and pneumatics, factors such as pressure losses and leakage can significantly impact performance, thus influencing the conservation of energy. Engineers and designers must adopt a holistic approach that considers these myriad facets to augment mechanical energy conservation.

Another crucial consideration is external forces, which can alter the conservation of mechanical energy in any system. Gravity, magnetism, and other environmental forces can have substantial effects on the mechanical energy of objects. In gravitational systems, for example, the potential energy of an object increases as it rises and decreases as it falls. However, if external forces act upon an object, such as wind resistance or other resistance forces, the efficiency of energy conservation can be compromised. Additionally, the presence of variable air pressure or atmospheric conditions can alter the dynamics of movement, further complicating energy conservation.

Temperature also plays a vital role in mechanical energy conservation. As temperature fluctuates, the properties of materials change. For example, the viscosity of lubricants decreases at higher temperatures, which can influence friction and, consequently, energy losses. Additionally, thermal expansion may affect how components fit together, potentially leading to inefficiencies. Understanding these thermal dynamics is essential for maintaining optimal energy conservation across different operating conditions.

Human factors, such as operator behavior and maintenance practices, can also influence mechanical energy conservation. Trained operators are essential for maximizing the efficiency of machines and minimizing energy losses. Regular maintenance can mitigate the effects of wear and tear on components, ensuring that systems function optimally. Ignoring maintenance can lead to increased friction and reduced energy conservation, emphasizing the importance of a proactive approach.

Finally, advancements in technology play a pivotal role in enhancing mechanical energy conservation. Innovations in materials science have yielded lighter and stronger materials that can withstand greater stresses while minimizing energy loss. Moreover, the integration of smart technologies, such as sensors and automation, allows for real-time monitoring of systems. This technological integration can provide valuable data for optimizing performance and identifying inefficiencies, thereby enhancing mechanical energy conservation.

In conclusion, mechanical energy conservation is a multifaceted topic influenced by various factors ranging from physical properties to external conditions and human practices. Understanding and addressing these factors is vital for engineers, scientists, and environmentalists alike. By emphasizing efficient designs, reducing friction, and leveraging technological innovations, it is possible to optimize the conservation of mechanical energy. In doing so, we not only enhance the performance of our systems but also contribute to sustainable practices that benefit the environment and society as a whole.