The tire industry has experienced profound transformations in response to the growing exigencies posed by climate change. The interlinkage between global warming and economic stability necessitates the adaptation of various sectors, with the tire industry standing at a crucial crossroads. This sector, vital for transportation, encapsulates the need for sustainable practices and innovation. This discourse explores the evolutionary trajectory of the tire industry, detailing its responses to climate challenges and the implications for economic shifts.

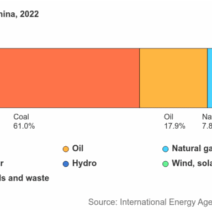

Initially, the tire industry has been criticized for its substantial carbon footprint. Traditional tire manufacturing processes rely heavily on fossil fuels, not only in the production of raw materials but also in the operational phases of manufacturing. However, with a burgeoning awareness of climate change, tire manufacturers are increasingly pivoting towards eco-friendly practices. This transition is characterized by a move towards sustainable materials, such as bio-based rubber derived from renewable sources, and recycling initiatives aimed at curbing waste.

One of the most promising advancements in the tire industry is the development of tires manufactured from sustainable materials. For instance, certain manufacturers are experimenting with natural rubbers sourced from sustainably managed plantations. This contrasts starkly with synthetic rubbers that are petroleum-based. The use of bio-materials not only diminishes the reliance on fossil fuels but also contributes to reducing greenhouse gas emissions associated with production processes.

Moreover, innovations in tire design are also noteworthy. Modern tires are engineered to enhance fuel efficiency. Low rolling resistance tires can significantly improve vehicle fuel economy by minimizing energy loss as the tire rolls. This efficiency not only translates to cost savings for consumers but also reduces overall carbon emissions. As governments worldwide implement stricter environmental regulations, the adoption of low rolling resistance technology becomes not just advantageous but essential for compliance.

In tandem with technological upgrades, the tire industry’s operational aspects are witnessing transformative changes as well. The implementation of circular economy practices has gained momentum, where recycling and reusing materials are prioritized. Some companies have initiated take-back programs that encourage consumers to return old tires. These tires can then be processed for reuse, either in new tire manufacturing or as raw materials for other products, reducing the overall waste generated by the industry.

Further emphasizing the industry’s commitment to sustainability, the shift towards electric and hybrid vehicles presents an opportunity for tire manufacturers to innovate. Tires specifically engineered for electric vehicles (EVs) demand unique characteristics, such as enhanced durability and optimized performance due to the distinct weight and torque properties of electric drivetrains. Developing tires tailored for EVs is not merely a response to changing consumer demands; it represents a proactive approach to aligning with global efforts to reduce reliance on fossil fuels.

Financially, the tire industry’s adaptation to these climate-related economic shifts is becoming increasingly significant. Investors are favoring companies that demonstrate a strong commitment to sustainability, leading to a reallocation of capital towards green technologies. This shift in investment paradigms means that companies that fail to adapt may struggle to secure funding, jeopardizing their long-term viability. Reports suggest that consumers are also showing a preference for brands that adhere to sustainable practices, compelling companies to re-evaluate their corporate strategies.

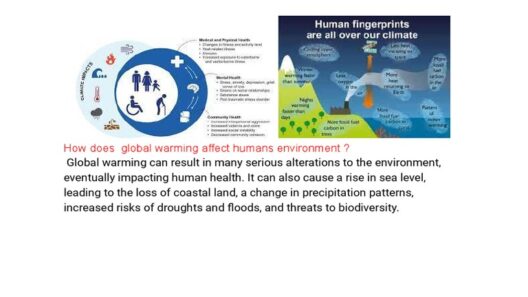

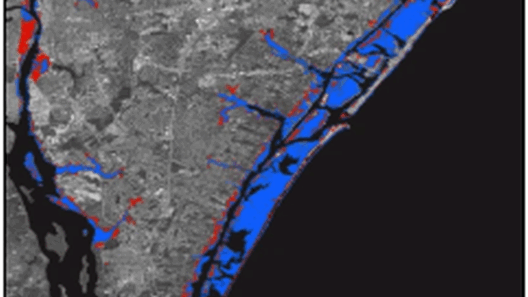

The implications of these adaptations extend far beyond mere compliance with regulations or consumer preferences. They encapsulate the broader economic narrative of resilience in the face of climate adversity. As extreme weather events become more frequent due to climate change, the tire industry must also consider the operational risks posed by such occurrences. Manufacturing plants located in flood-prone or fire-prone areas may need to reevaluate their logistics and supply chains to mitigate disruptions.

Furthermore, the tire industry’s connection to global supply chains highlights a need for transparency and ethical sourcing. As climate change risks compound, the understanding of supply chain vulnerabilities becomes essential. Ensuring that raw materials are sourced sustainably not only contributes to environmental goals but also secures the supply chain against potential disruption caused by adverse climate impacts.

The tire industry’s path toward sustainable adaptation is also subject to public perception and corporate responsibility. Engaging consumers through education about the environmental impact of tire choices plays a pivotal role in driving demand for greener alternatives. As consumers become more environmentally conscious, tire manufacturers that actively communicate their sustainable efforts are more likely to gain consumer loyalty.

In conclusion, the tire industry’s adaptation to the economic shifts driven by climate change underscores a significant evolution in both its operational models and its material usage. The proliferation of sustainable technologies and practices reflects a broader movement within industries striving to align profitability with responsibility. As the world grapples with the intricacies of climate change, industries like tire manufacturing must lead the charge towards innovative solutions that not only satisfy market demands but also foster a sustainable future for the planet.