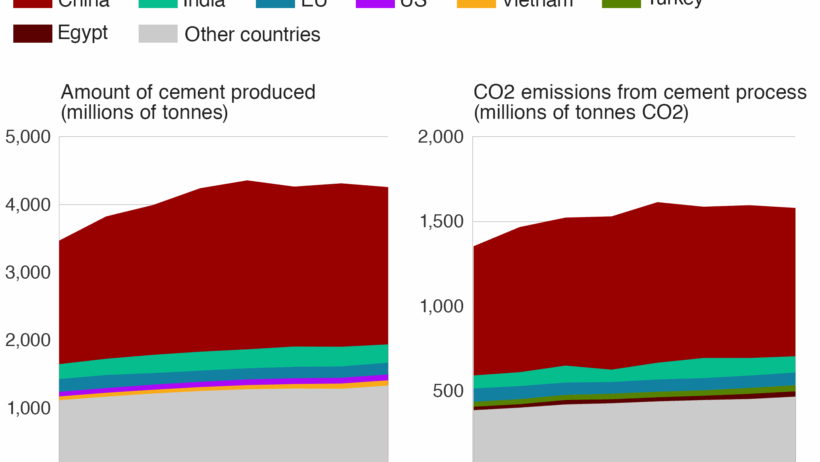

The global conversation surrounding climate change often centers on carbon emissions from vehicles and industrial processes, yet an often-overlooked contributor to greenhouse gas emissions is cement manufacturing. The ubiquitous nature of concrete, a product of cement, disguises the significant environmental footprint associated with its production. When delving into the hidden ramifications of cement on our planet, it is essential to elucidate how this seemingly innocuous material exacerbates global warming.

Cement is composed primarily of limestone, clay, and other materials that undergo a highly energy-intensive process known as calcination. During calcination, limestone (calcium carbonate) is heated to high temperatures, resulting in the release of carbon dioxide (CO2). This thermal decomposition occurs in kilns operating at temperatures exceeding 1,400 degrees Celsius. Alarmingly, the cement industry accounts for approximately 8% of the world’s total CO2 emissions, putting it on par with the emissions of entire countries. This category of emissions is termed Scope 1 emissions, as they originate directly from the combustion of fossil fuels and the chemical reactions that occur during the production process.

Moreover, the energy expended in cement production predominantly relies on fossil fuels, further compounding the industry’s carbon footprint. Although some manufacturers are exploring alternative energy sources, such as biomass and solar power, the majority of cement is still produced using coal, natural gas, and other non-renewable resources. As global demand for concrete continues to surge—bolstered by urbanization and infrastructure development— the urgent need for sustainable practices in cement production becomes pronounced.

As societies strive to mitigate climate change, understanding the life cycle of cement is imperative. From the extraction of raw materials to the final disposal of concrete, each stage has implications for environmental sustainability. The extraction process, often conducted through quarrying, generates substantial ecological disruption, habitat loss, and often leads to soil erosion. Once formed, cement itself possesses a longevity that is paradoxical: while concrete’s durability makes it a favorable choice in construction, it also means that the CO2 emitted during its production remains in the atmosphere for decades.

While the conventional approach to addressing cement’s carbon footprint has centered on reducing emissions, innovations are emerging that promise a transformative leap in the industry’s environmental impact. The development of lower-carbon alternatives can revolutionize cement production. Some companies are exploring formulations that incorporate industrial byproducts, such as fly ash or slag, which can significantly reduce the carbon intensity of concrete. Additionally, novel techniques like carbon capture and storage (CCS) are being tested to sequester emissions produced during manufacturing before they enter the atmosphere.

Another potential avenue is the rise of geopolymer cements, which utilize waste materials in their production rather than limestone. These alternative cements can reduce CO2 emissions by up to 80% compared to traditional Portland cement. The widespread adoption of these innovations is currently hindered by several factors, including regulatory frameworks, market conditions, and a lack of public awareness. However, a paradigmatic shift towards sustainable practices in cement production could play a pivotal role in achieving global climate targets.

On a broader scale, the collaborative efforts between governments, academia, and the private sector are vital for fostering innovation in the cement industry. Knowledge-sharing and investment in research can lead to the development of greener technologies. Policy mechanisms, such as carbon pricing and incentives for using alternative materials, are crucial for incentivizing change. The integration of circular economy principles in construction can further enhance sustainability by promoting the reuse of materials and minimizing waste.

Beyond manufacturing, the conversation surrounding cement extends into the realm of construction practices and the entire built environment. Enhancing energy efficiency in buildings and infrastructure can significantly curtail the demand for cement. Retrofitting existing structures, implementing passive design principles, and utilizing smart materials can all contribute to reduced consumption of concrete. In alignment with sustainable architecture and urban planning, a paradigm shift is necessary to rethink how we develop our cities and manage our resources.

Public awareness and engagement are also vital in catalyzing change within the cement industry. Initiatives aimed at educating communities about the carbon footprint of their built environment can lead to more responsible consumption patterns. Cities and municipalities can play a critical role by advocating for green building standards that prioritize low-carbon materials. By fostering a culture of environmental stewardship, individuals can contribute to decreasing the reliance on conventional cement applications.

The journey towards sustainable cement production is fraught with complexities, but opportunities abound for innovation and reform. The cement industry stands at a crossroads: it can continue its path, contributing to the climate crisis, or embrace a transformative future centered on low-carbon solutions. The onus lies with all stakeholders to catalyze this shift. By reassessing our relationship with cement and embracing sustainable alternatives, we can collectively mitigate its contribution to climate change.

As the world grapples with the realities of climate change, acknowledging and addressing the role of cement is vital. This unseen culprit, while foundational to modern infrastructure, carries a significant environmental burden. It is time to confront these realities and pursue a sustainable path forward that preserves the integrity of our planet for generations to come.