The phenomenon of global warming is an intricate web of causation, and at the heart of this complexity lies an often overlooked contributor: factories. These behemoths of industry, while miraculous in their ability to produce goods at an astonishing pace, harbor an unseen ecological footprint that exacerbates climate change. Understanding the multifaceted relationship between industrial emissions and global warming is crucial in re-evaluating our approach to environmental conservation.

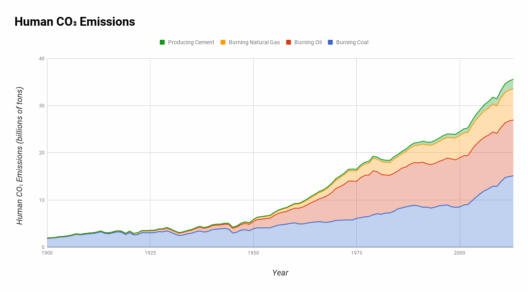

To comprehend how factories fuel global warming, one must first grasp the underlying mechanics of greenhouse gas emissions. Factories predominantly release carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O) into the atmosphere—each gas potent in its capacity to trap heat. The sheer volume of gases emitted from manufacturing processes inevitably accumulates, forming a dense blanket that envelops the Earth and shrouds it in an increase of temperature. This causal chain is alarming, yet the complexities of industrious emissions extend far beyond mere figures of pollution.

Consider a modern factory. It functions not only as a site of production but also as an apparatus of energy consumption. Manufacturing operations are notorious for their insatiable appetite for electricity, often derived from fossil fuels. In the United States, for instance, a substantial portion of power generation relies on coal and natural gas. When these fuels are combusted, they release massive quantities of CO2. Therefore, every item that rolls off a factory assembly line potentially bears the burden of its greenhouse gas emissions. The manufacturing sector, in fact, is responsible for nearly 20% of the global emissions total, a figure staggering enough to beckon immediate scrutiny.

However, it is imperative to recognize the broader spectrum of emissions that factories generate. Industrial processes involve not just energy consumption but also the release of a range of hazardous pollutants, including volatile organic compounds (VOCs) and particulate matter. These substances, in addition to their health implications, interact with atmospheric phenomena in ways that can exacerbate warming. For example, certain VOCs can lead to the formation of ground-level ozone, a greenhouse gas that contributes significantly to the greenhouse effect.

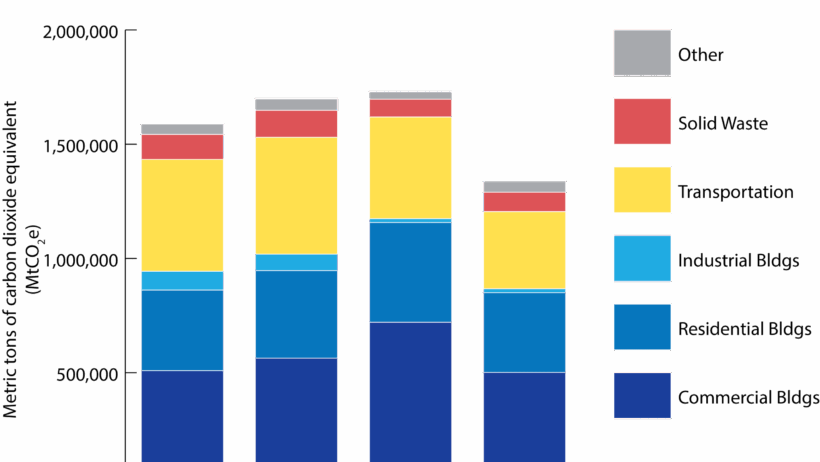

Another critical component in this equation is waste. Factories produce substantial amounts of wastewater and solid waste, which, if improperly managed, can emit methane—a gas greenhouse gas that is roughly 25 times more potent than CO2 over a 100-year period. Landfills, where industrial waste often ends up, become significant sources of methane emissions. Thus, without effective waste management strategies, the factory’s unseen footprint can grow disproportionately, further contributing to climate change.

The transportation of raw materials to factories and finished products to consumers represents yet another layer of emissions. The logistics of transportation involve delivery trucks, ships, and trains, all of which typically rely on fossil fuels. Each leg of transportation adds another dimension to the carbon footprint of a single product. When one considers the globalized economy, where goods traverse thousands of miles before reaching their destination, the cumulative impact becomes undeniably substantial.

Yet, is all hope lost? The narrative surrounding factory emissions, while daunting, is not devoid of solutions. There is a growing movement within industries advocating for sustainability and innovation. Concepts such as circular economy and green manufacturing are gaining traction and highlight the potential for a paradigm shift. By re-thinking production processes, companies can minimize waste, lower their carbon footprints, and increase efficiency. For instance, initiatives to repurpose waste materials can reduce both emissions and resource extraction pressures, effectively transforming a linear consumption model into a regenerative one.

Renewable energy emerges as another promising avenue. Transitioning from fossil fuels to solar, wind, and hydroelectric power for manufacturing operations can substantially lower greenhouse gas emissions. Companies across the globe are beginning to harness these cleaner energy sources, not only as an ethical responsibility but as a critical business strategy in a world increasingly oriented toward sustainability.

Furthermore, advancements in technology offer hopeful innovations. The implementation of automated systems and artificial intelligence can optimize production efficiency, thus reducing waste and energy demands. Enhanced industrial processes, such as 3D printing, promise to revolutionize manufacturing by minimizing waste and decreasing the need for transportation.

On an individual level, consumers can exert significant influence by advocating for sustainability and supporting eco-friendly companies. This activism can drive market demand, encouraging other businesses to adopt similar practices. Education and transparency in manufacturing processes empower consumers to make informed choices that prioritize environmental considerations.

In conclusion, understanding the unseen footprint of factories on global warming invites a re-evaluation of industrial practices. The interplay between manufacturing, emissions, and climate change presents a multifaceted challenge—but also an opportunity for transformation. By embracing innovative technologies, sustainable practices, and conscious consumer behavior, we can shift the narrative toward one of hope and restorative action. The stakes are high, but collective effort can forge a path toward a more sustainable future where industries contribute to environmental stewardship rather than degradation. The future depends on what we choose to do today, and it is upon us to pivot our trajectory towards a greener, more sustainable planet.