Understanding the dynamics of mechanical energy is fundamental in both physics and engineering disciplines. Mechanical energy refers to the sum of kinetic and potential energy in a system. According to classical mechanics, energy is typically conserved in closed systems. However, there are numerous scenarios where mechanical energy is not conserved, influenced by various forms of energy transfer and losses. This article aims to delineate the circumstances under which mechanical energy can be lost, explore the underlying principles, and provide insights on practical implications.

The principle of conservation of mechanical energy asserts that in an isolated system without external forces, the total mechanical energy remains constant. Nevertheless, in real-world applications, several factors can disrupt this balance. Understanding these factors is essential for scientists, engineers, and anyone involved in practical physics.

Factors Leading to Non-Conservation of Mechanical Energy

An array of factors can induce the loss of mechanical energy from a system. These factors typically arise from the interactions of physical objects and the environment, leading to energy dissipation in varied forms.

Friction: The Silent Energy Drainer

One of the most prevalent causes of lost mechanical energy is friction. When two surfaces interact, they generate frictional forces that dissipate kinetic energy as thermal energy. For instance, a sliding block experiences a reduction in speed due to friction exerted by the surface it moves over. This conversion of mechanical energy into heat exemplifies a common scenario where mechanical energy is not conserved. This principle is critical in mechanical engineering, requiring careful consideration in system design to minimize energy losses.

Air Resistance: The Invisible Barrier

In many outdoor applications, air resistance, or drag, plays a significant role in the dissipation of mechanical energy. As an object moves through the air, it must work against air molecules, which leads to a loss of kinetic energy. This phenomenon is especially relevant in sports, engineering, and aerodynamics. Sports cars, for example, experience a significant drop in performance when accounting for air resistance, necessitating designs that minimize drag to maintain energy efficiency.

Internal Energy Losses: Deformation and Fracture

Systems are not always perfectly rigid. Internal structural changes, whether due to deformation or fracture, can lead to significant losses of mechanical energy. When materials bend or break, energy is absorbed by the constituents of the material, often manifesting as heat or sound. This absorption reduces the amount of mechanical energy that is available for doing work. Engineers must take this into account when selecting materials and designing structures, ensuring that energy losses are kept within acceptable limits.

Time-Dependent Factors: The Role of Damping

Damping is another critical aspect that dictates when mechanical energy is not conserved in a system. Damping is the process through which vibrational energy is lost due to resistance forces, often from air resistance or material properties of the system itself. For example, in mechanical oscillators, energy is continually lost to the environment, leading to a gradual decrease in the amplitude of oscillations over time. Understanding damping is essential for various applications, including the design of shock absorbers in vehicles, where it is imperative to control energy dissipation effectively.

Implications of Non-Conservation of Mechanical Energy

The implications of non-conserved mechanical energy penetrate several fields including engineering, environmental science, and technology. Acknowledging these losses allows for more efficient systems, sustainable practices, and innovative designs.

Engineering Innovations: Enhancing Efficiency

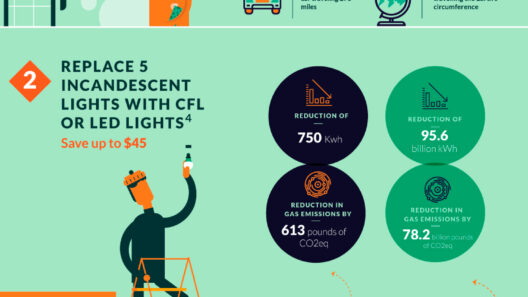

In engineering, the goal is often to create systems that maximize output while minimizing energy losses. Recognizing where mechanical energy is lost enables engineers to design better mechanisms. For instance, in automotive engineering, advancements in aerodynamics and materials technology have continuously improved fuel efficiency, reducing energy losses through friction and drag. Hybrid vehicles exemplify how integrating energy recovery systems can compensate for energy losses and maintain mechanical advantage.

Sustainability Considerations: The Environmental Impact

From an environmental perspective, optimizing mechanical energy use can lead to more sustainable practices. Reducing energy losses not only enhances efficiency but also diminishes the overall carbon footprint associated with energy production. By promoting systems that minimize mechanical energy dissipation, industries can contribute to a more sustainable future, aligning with global efforts to combat climate change.

Technological Advancements: Opportunities for Innovation

In the realm of technology, the exploration of non-conserved mechanical energy opens avenues for innovation. Researchers continually investigate materials and designs that mitigate energy losses. For instance, the development of superconducting materials illustrates a potential for minimizing resistance in electrical systems, indirectly enhancing mechanical energy conservation in electromechanical systems.

Incorporating the understanding of when and why mechanical energy is not conserved is essential for advancing scientific inquiry and practical applications. By recognizing and addressing the various factors that lead to energy dissipation, professionals across disciplines can work towards creating more efficient, sustainable, and innovative solutions for a myriad of applications.